Southern Company Upgrades its Business Operations with PowerPlan Solutions

Background

|

Southern Company | ||

|---|---|---|

|

Headquarters

Atlanta, Georgia |

Metered Customers

4.417 million |

Business

Retail electric service |

|

2010 Revenue

$17.456 billion |

Founded

Mid-1920s |

Employees

26,000 |

|

Total Assets

$55.032 billion |

Generating Capacity

42,963 megawatts |

“ When comparing PowerPlan to other alternatives, PowerPlan’s application screens and navigation through the application were found to be much more intuitive and user-friendly.”

Accounting Services Manager, Southern Company Services

Southern Company selected project and cost management solutions from PowerPlan to make its business operations in Generation more efficient and precise. These solutions are a critical component of an overall process and technology transformation being rolled out system-wide.

Key Challenges

- Upgrade: Southern Company sought to improve its project and cost management, forecasting and budgeting capabilities in order to drive operational efficiencies and support more effective decision-making. Its existing systems couldn’t provide sufficient, timely or detailed information and were labor-intensive and expensive to maintain.

- Costing: The utility needed visibility into granular cost details for operations and maintenance (O&M), but the homegrown legacy accounting system only tracked information at the account number level. To optimize business operations, it needed for some business units to track and report accurate, actual asset-related costs down to the work order level — a process that the new EAM and ERP systems could not support without customizations.

- Budgeting: Generation sought to improve its budget control through management of asset and asset group costs, such as systems, pumps and motors. The ability to capture accurate capital and real-time O&M actuals and enable comparisons to budget in a single tool would provide real benefits in terms of budget awareness and management.

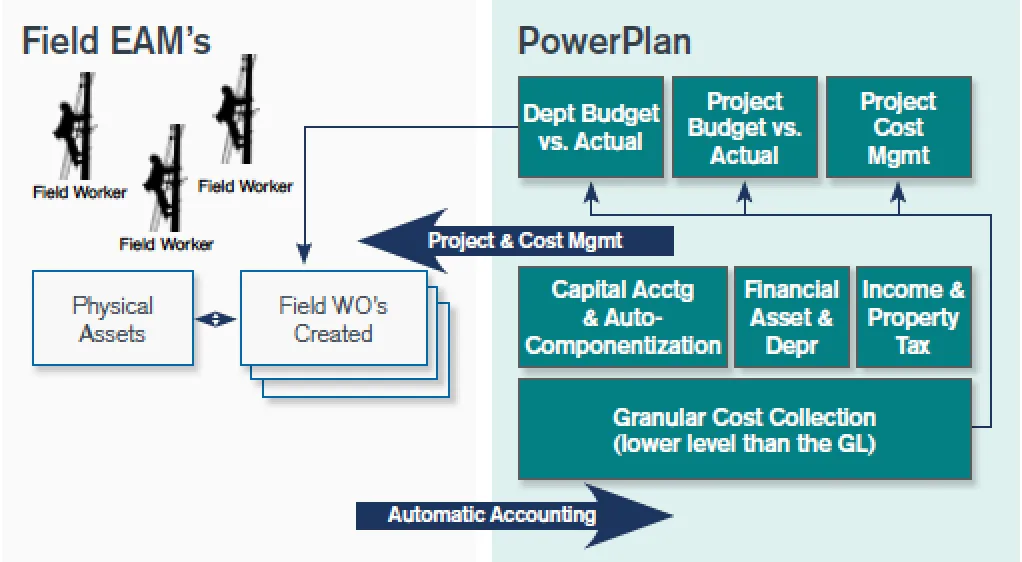

- Projects: For projects, the accounting burden needed to be kept out of the field operations. For Generation, work breakdown structures and asset/location hierarchies needed to reflect the work performed rather than the accounting. Cost structures needed to be derived automatically from the EAM.

- Reporting: Southern Company needed all information reported to be as real-time as possible. It sought standard and ad hoc reporting and query capabilities that were simple, flexible and user-friendly.

- Reliability: Optimizing asset management through improved cost management and visibility would lead to increased asset reliability.

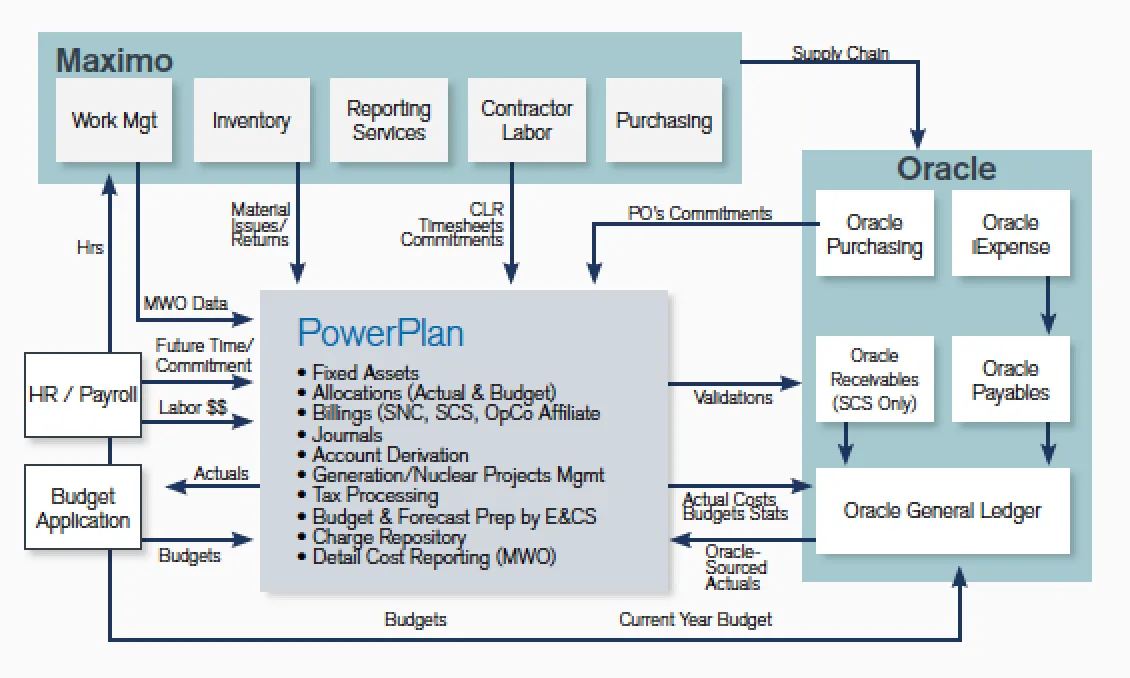

- Integration: The new solution would become the integration hub of Southern Company’s larger Enterprise Solutions initiative, which replaces multiple legacy systems and manual processes with system consolidation and automation. Therefore, it needed to readily integrate with the utility’s new ERP, EAM and project scheduling applications.

- Compliance: The software provider needed to be a trusted partner committed to maintaining regulatory and accounting compliance, and the solution needed to be configurable to support future requirements.

“We always wanted to take our costs down to the plant asset level, and with PowerPlan we can track to the Maximo work order and equipment ID. Receiving cost data from PowerPlan in near real time at this level is a huge benefit. In addition, the PowerPlan software was very easy to learn. Before I went through a day of training, I was able to sit down and use this software.”

Enterprise Solutions Director, Southern Company

Decision Drivers and Implementation

After considering its options, Southern Company chose solutions from PowerPlan to enhance its project and cost management abilities. The capital side of the business had consolidated on PowerPlan’s core fixed assets software to improve compliance, automation and efficiency, and it was determined there was a good fit for Operations and Maintenance use for select business units.

PowerPlan delivered the expertise, functionality and synergy with Maximo and Oracle Financials that were needed. The application’s screens, navigation and reporting capabilities were effective and intuitive, whereas the alternatives would have required customizations. The utility was further impressed by PowerPlan’s willingness to consider the value of a requested feature and add improvements to the base product. And, as a bonus, PowerPlan offered a journal prep tool that met a key business requirement.

As a next step to further improve their operations, the PowerPlan Capital Budgeting and Project Management modules were selected as well as Tax Provision and Lesse Accounting. The PowerPlan implementation coincided with the phased Enterprise Solutions rollout to Southern Company’s five Generation business units. Three of the operating companies are currently live, and the rollout is complete. PowerPlan is already live at all Southern Company entities for core financial functionality such as journals and cost allocations.

Southern Company’s Business Benefits with PowerPlan’s Suite

- Cost Management: PowerPlan is now the central tracking mechanism for the large majority of Southern Company’s $55 billion of assets. With costs at the plant asset level, PowerPlan is a fully balanced subledger to the G/L while holding transactions at a very low level of detail for Generation. The information in Southern Company’s reports and queries is more effective now that actual and projected costs are aggregated in real time, and cost data is exchanged between Maximo, Oracle and PowerPlan in near real time.

- Budget Compliance: The ability to have budgets and costs in a single system is expected to improve the ability of Generation to manage asset budgets by plant, unit, system and sub-system. Since implementation, the Generation business unit has not been through a budget cycle using PowerPlan but to-date cost data provided at the asset level is providing an early indication of the ability to improve budget compliance. With more accurate and timely information, budget constraints at higher levels can be more effectively deployed.

- Project Management: The process of initiating and monitoring work orders and projects is simplified in the new system. The utility has access to specific costs and is tracking budgets to actuals. The Engineering and Construction Services organization is generating realistic forecasts using real-time data and spread/ curve patterns that can be defined to support budgeting and forecasting to any level of the work breakdown structure.

- Financial Optimization of Assets: Better, more timely information is a key enabler of improved asset reliability and asset life expectancy. PowerPlan aligns the work-related data structures in the EAM system with the accounting-related structures in the ERP. It layers on budget and commitment information, thus allowing field operations to make sense of their spend, to strategically allocate resources and dollars, and to forecast and communicate those decisions. The level of alignment is flexible down to a single critical piece of equipment, the class of equipment across multiple locations, a subsystem or system, the station in total, or the company.

- Fewer Bigger Systems: Southern Company was able to retire 22 systems and an untold number of spreadsheets with the implementation of the platform shown below:

“PowerPlan’s consultants demonstrated their understanding of utility business requirements, and PowerPlan offered an overall better functional fit for Southern Company’s requirements in the areas of project costing and reporting.”

Accounting Services Manager, Southern Company Services

Southern Company’s Summary of Operational Benefits

The PowerPlan project resulted in a number of operational benefits across Southern Company. First, it has automated the generation of accounting and unitization rules from naturally present work information. This allows for fewer work orders to be created in the EAM system. Next, the implementation has allowed work breakdown structures and asset hierarchy to represent the actual work completed instead of an “Accounting Breakdown Structure.”

The project allows for cumulative period true-up so that operations doesn’t have to know everything at the outset. At the same time, it has automated accounting true-up to as-builts without manual journals. Best of all, the system provides cost feedback to operations at least daily, at any level of detail (including actual vs. budget, down to the task, equipment ID, location and cost-element level). In addition, it aligns with EAM data structures and rollups for location and equipment hierarchies, as well as corporate and account hierarchies. Lastly, the integrated PowerPlan solution allows for daily labor and contractor commitment costing and processing.

The result: less accounting, fewer work orders, better financial results, and more focus on operations.

Share

About

Atlanta-based Southern Company is one of the largest electricity generators in the nation. It serves both regulated and competitive markets in a territory spanning more than 120,000 square miles, including parts of Alabama, Georgia, Florida, and Mississippi.